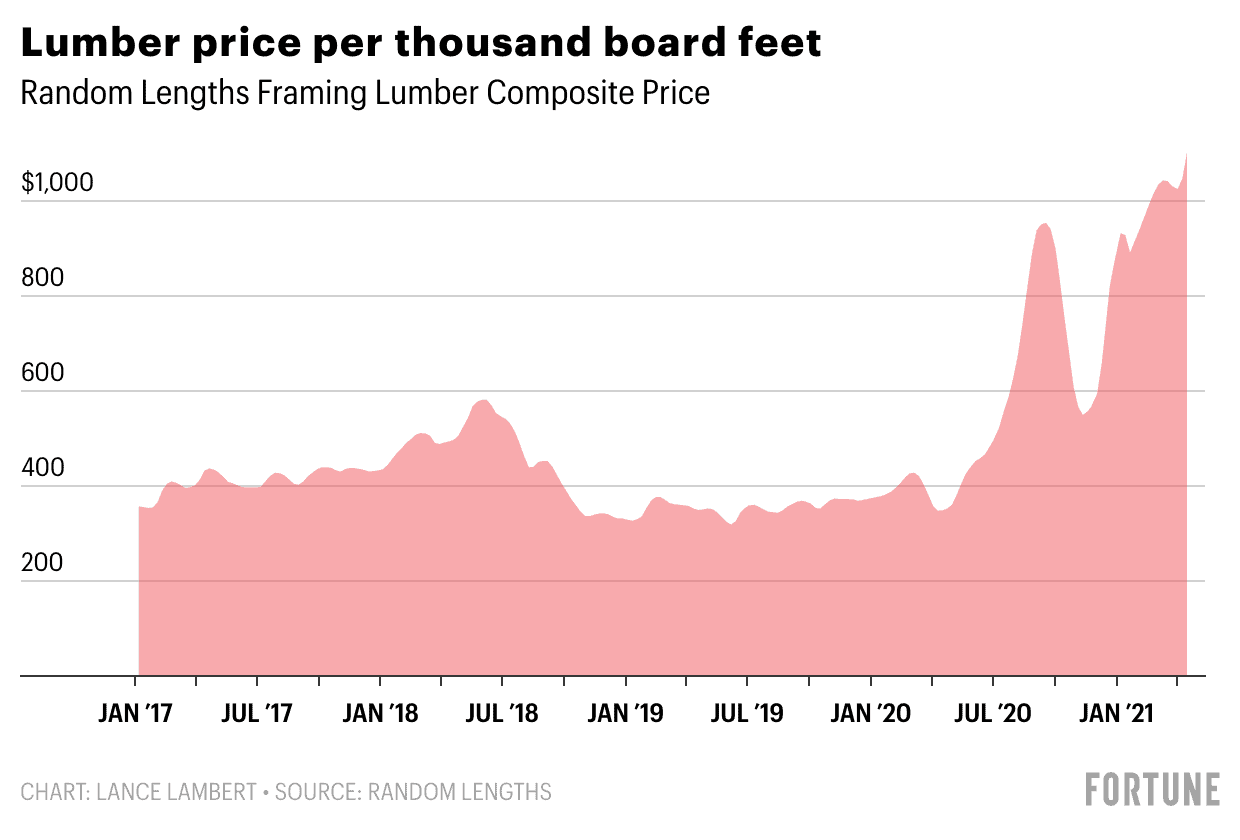

When it comes to the different types of softwood, there are many grades and varieties. Knowing what they are and how to tell them apart is important for your next building project. with lumber prices rising more than ever (up to $1,000/thousand board feet), it’s also important so you can maximize your budget and prevent wasting money.

This blog post will introduce you to each type and grade of softwood and let you know when each one should be used.

Common lumber grades

These are some of the common lumber grades to understand before purchasing lumber for your next project. Check out our lumber selection while you’re at it too.

No. 0 Common/Stud

This is a higher quality version because all parts are clear without any knot, holes, or split in them. They have fewer defects than the No-Construction common variety which makes them much easier to work with too. This one would be considered better to use as long as you’re okay dealing with some stains on your project.

No. 1 (Construction) Common

This is a very rough grade of wood that has been damaged by the elements or insects. It’s not suitable for building fine furniture, but can be used in construction projects or other industrial applications. There might still be nails and screws stuck in this type of lumber so caution should be taken when handling it.

No. 2 (Standard) Common

This is what you would traditionally think of as lumber. It’s not considered high quality, but it can be used on certain projects that don’t require very fine woodworking or staining since there are many small defects in the material. This type of wood is also sometimes re-sanded and stained to create a higher grade for sale at home improvement stores like Lowes or Home Depot so pay attention when buying. ML Group offers some of the highest quality lumber products, check them out there.

No. 3 (Utility)

These are boards that have more than one knot or hole in them, but they are still solid pieces of wood that can be used for construction-grade projects where the strength of the material is important and not its visual appeal. Used for pallets, subflooring/sheathing, beams, posts & poles, flooring joists.

This type of board should not be sanded due to its coarse surface unless it’s being reused as a structural piece since you would lose too much thickness if attempting to smooth out dents on the exterior side only using fine-grit paper. It might also need to be stained depending on how noticeable any knotholes or knots are.

No. 4 (Economy)

This lumber normally has numerous splits and knotholes with large waste areas. It does not take paint well and is primarily used for sheathing, subflooring, and concrete formwork.

No. 5 (Economy)

Expect larger waste areas and harsher defects. It has similar uses to No. 4.

Appearance Lumber Grades

Select lumber is excellent in terms of appearance and quality. This type of wood can be used for panelling, window frames, or decorative purposes. The reason why this type of software has such high demand is that it provides the best value when you want to purchase something that looks great without spending too much money on it.

On the other hand, select grades tend to have small knots and very little character which means they are not ideal if there’s going to be any kind of stain put on top of them. Furthermore, these types of softwood cannot tolerate heavy loads like floor joists and roof rafters where pressure-treated material would excel better due to its strength (which we discuss below).

A Select

Doesn’t display knots, splits, or visible defects.

B Select

May contain some small visible defects.

C Select

Expect this wood to contain small knots. Some sides will be completely free of defects.

D Select

This grade and designation usually have pin knots and other tiny blemishes.

No. 1 Common

Has a knotty appearance but is tight and not likely to fall out.

No. 2 Common

Similar to No. 1 Common but the knots are larger.

Stress-Graded Lumber Grades

These are grades of lumber that are graded, or ranked by strength. Normally these are used for beams, posts, or rafters. Anything that has to be made to be weight-bearing will most likely use stress-graded lumber.

| Designation | Grade | Use |

| Structural Light Framing | Select Structural | Great for strength but can also be used for a good appearance. For sizes 2×2 through 4×4. |

| No. 1 & BTR | ||

| No. 1 | ||

| No. 2 | ||

| No. 3 | ||

| Light framing | Construction | Ideal for wall framing, blocking, plates, and other applications where the highest strength value isn’t needed. For sizes 2×2 through 4×4. |

| Standard | ||

| Utility | ||

| Stud | Stud | This is used for vertical loading-bearing applications For sizes 2×2 through 4×18. |

| Structural Joists & Planks | Select Structural | Used for applications like headers, trusses, floor and ceiling joists, and more. For sizes 2×5 through 4×18. |

| No. 1 & BTR | ||

| No. 1 | ||

| No. 2 | ||

| No. 3 |

Wrapping up grades of softwood

Softwood lumber is an incredibly versatile material that can be used for floors, rafters, headers, and everything in between. However, it’s important to understand the grades of softwood for the best results. Otherwise, you might buy the wrong product and waste your money. Use the information in this article as a reference for your future projects and you’ll always make the right decision.

Make sure to browse our lumber products and building materials for your next project as well.